KUKA Systems Partner

KUKA Systems Partnership

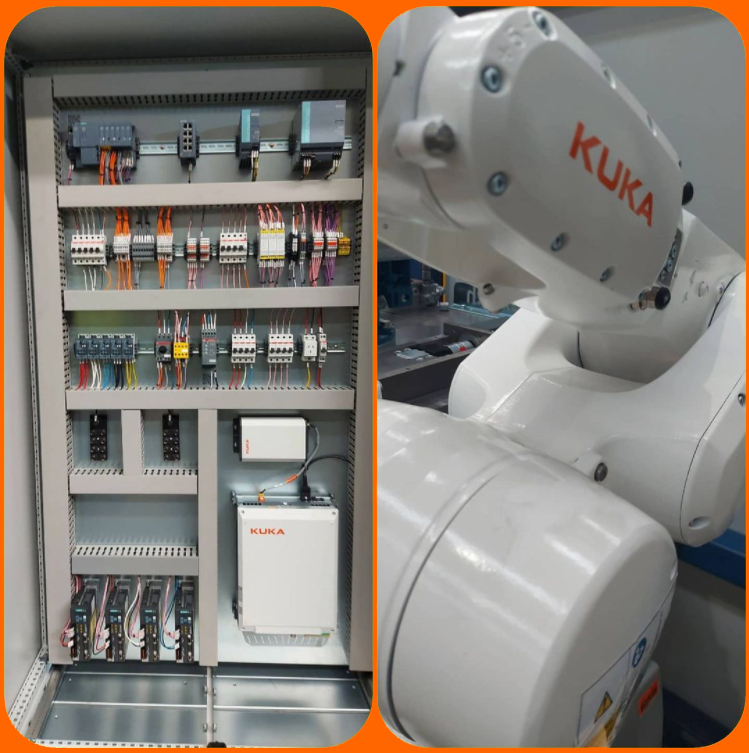

CellTec has teamed up with world leading automation and robot specialist KUKA to offer our customers innovative intelligent solutions.

With combined knowledge in the automotive, warehousing / e-commerce retail, food & beverage handing, manufacture assembly and healthcare industries, we can assess, design and provide automation solutions to reduce costs and downtime with a smooth and productive workflow.

Integration Specialisation:

- Mechanical and Electrical design expertise and experience

- PLC and HMI programming for seamless operation and data logging requirements

- In house manufacturing facilities to provide custom fabrication and adaptability

- Designing solutions with workflow in mind to achieve productivity goals

- Extensive network of electrical, mechanical and safety product resources for best fit solutions

Industries:

- Assembly – industrial, construction, electronics and commercial products

- Manufacturing – welding and automated construction

- Food & Beverage – production and palletising

- Pharmaceutical, medical, healthcare

- Warehousing and Logistics – B2B, Retail & E-Commerce

Solutions:

- Parts assembly incl. custom designed operation and tooling

- Welding and metal fabrication – with options of automated, manual or

combined loading - Specialist Applications – to improve specific production bottlenecks and

increase productivity - Custom product assembly, packaging and palletising

- Workflow focused systems to decrease production downtime and

improve handling ergonomics

Project Highlight: Clinching Twin Robots and Positioner Rollover

Customers’ Requirement:

Increase production capacity with automated frame construction / clinching.

How we got there:

- Twin KUKA KR 120 R2500 Pro Robots with dynamic flexibility and reach.

- Kuka Linear Positioner in order for loading and clinching to occur simultaneously, increasing production to growth targets.

- BTM 10 TON Hydrualic Arm Units removing multiple manual clinching points to operation by duel rotating robot clinch arms.