ABB 580 VSDs: Making the choice easy, with Industry Specific Drives

Why not choose a drive that is suitable to your environment?

With ABB’s 580 industry specific VSD series you don’t need to compromise your objectives and output goals. The 580 model VSDs are part of ABB’s all-compatible portfolio, sharing the same architecture and user interfaces for easy usability.

Compatibility for future development and growth. Benefits of choosing a drive from the all-compatible portfolio:

Adaptive programming

• Firmware includes an easy-to-use and visual adaptive programming feature.

• Adaptive programming can be used to add logical functions and conditions for process fine-tuning.

Same PC tools for ABB all-compatible drives

• Free Drive Composer: a start-up and maintenance tool for ABB’s common architecture drives.

• Same parameter structure makes the all-compatible platform easy to use.

ATEX-certified PTC thermistor support

• Can be equipped with an optional CPTC-02 ATEX-certified PTC sensor.

• The safety integrity level for the CPTC-02 module is SIL 2/PL c.

Connectivity

• Supports F-series fieldbus adapters used in the ABB all-compatible platform.

• Mobile phone connectivity via the optional Bluetooth assistant control panel.

• Fieldbus settings are made easy with the redesigned simple settings menu.

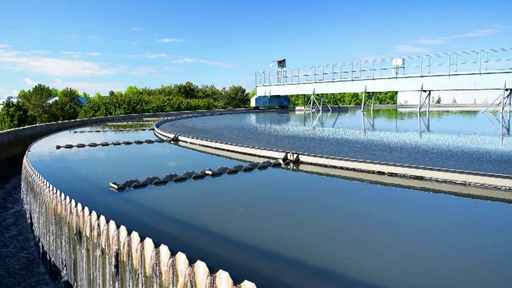

Water (ACQ580)

Robust design securing optimal flow of water and wastewater

ACQ580 drives secure the flow of water and wastewater; designed for water and wastewater pumps, blowers, mixers, centrifuges and fans.

Highlights

• Optimized efficiency of the water and wastewater process

• Enhanced reliability with dedicated pump application functionalities

• Proven performance in demanding environments with robust and compact drives offering

• Seamless integration and operation with wide motor and communication protocol support

• Easy to commission, configure and use with intuitive Hand-Off-Auto control panel that speaks pump language

Features

• Power range 0.75 to 500 kW (3-phase 380 to 480 V)

• Wall-mounted drives, IP21 as standard (UL type 1), IP55 as option (UL type 12)

• Drive module, IP00 as standard, IP20 as option

• Cabinet-built drives, IP21 as standard, IP42 and IP54 as options

• Built-in pump application program with Intelligent multi-pump functionality, Sensor-less flow calculation, Level control, Soft pipe fill, Quick ramps, Pump cleaning and Pump protection functions

• Adaptive programming

• Intuitive and easy to use Hand-Off-Auto control panel available also with Bluetooth functionality

• Built-in choke and EMC filter, category C2

• Functional safety: Safe torque off (STO) as standard

• Extended connectivity to I/O

• Coated PCBs as standard for humid and harsh environments

Soft pipe filling

Increase the lifetime of the piping and pump system by avoiding pressure peaks.

Quick ramps

Extend the lifecycle of a submersible pumps by reducing wear of the mechanical parts using ramp sets to accelerate and decelerate the pumps.

Pump priority

Achieve energy savings with optimal pump alternation by running the higher capacity pumps when the consumption rate is higher.

Multi-pump control

Ensure stable and uninterrupted production with multi-pump controls by optimizing the speed and number of running pumps.

Multi-pump control

Ensure stable and uninterrupted production with multi-pump controls by optimizing the speed and number of running pumps.

Sleep boost

Save energy while extending the life time of the pumps and motors by decreasing start/stop cycles during all hours of the day.

Auto-change

Increase the mean time between repairs and save in service costs by balancing the long-term operation time of all pumps in a parallel pumping system.

Level control

Ensures optimal efficiency when filling or emptying a tank.

Sensor-less flow calculation

Reduce costs by eliminating the need for external components or backup the flow meters to avoid interruptions in the process.

Flow and pressure protection

The drive protects the pumping system from a low and / or high pressure and flow, as well as prevents the pump from running dry.

Pump cleaning

Achieve savings by preventing unplanned downtime. This is made possible as a result of accumulating obstructions being removed from the impeller of the pump.

Want to learn more? Download below…

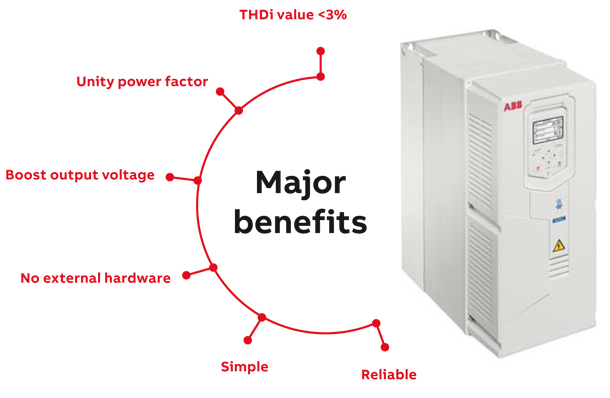

HVAC (ACH580)

Comprehensive climate control, effortless operation

ACH580 drives are ideal for the HVAC fans, pumps, compressors, air-handling units and chillers used in hospitals, data centers, shopping centers, tunnel ventilation, factories, office buildings, and more.

Highlights

• Complete HVAC functionality in a scalable package

• Simple to select, install and use, all the essential features are embedded inside

• Seamless integration to applications and job sites in languages users and systems speak

• Controls induction motors (IM) and energy efficient permanent magnet (PM) and synchronous reluctance motors (SynRM)

• Ultra-low harmonic version also available for more demanding applications

Features

• Premium drive for HVACR applications

• Power range 0.75 to 500 kW (3-phase 380 to 480 V)

• Wall-mounted drives: IP21 as standard, IP55 as option

• Cabinet-built drives: IP21 as standard, IP42 or IP54 as option

• Public networks compliant with standard EMC C2 filter and built-in swinging choke

• User friendly operation with HVAC control panel with Hand-Off-Auto functionality

• BMS communication embedded with BACnet MS/TP, Modbus RTU and N2

• Optional Bluetooth enabled HVAC control panel and Drivetune app allows the drive to be operated from a distance

• Loop controllers for controlling the speed of a fan or pump. Additional loop controllers to control external devices.

• Real time clock and built-in timers for timed operation of the drive and control of external HVAC devices

• Certified Safe torque off (STO) as standard

• The ultra-low harmonic drive variant ensures a pollution-free electric supply and allows the motor to be run at full voltage even in situations where the network voltage is reduced

Effortless system startup

The ACH580 ensures a smooth, coordinated start to your HVAC system. Embedded interlock logic enables the drive to confirm that equipment position, such as dampers, and sensor status are correct before operations begin.

Increased energy savings

Achieve increased energy savings by using the appropriate motor and drive combination. The ACH580 drive works with induction motors, PM motors, or SynRMs, which enable high efficiencies.

Improved safety

Built-in safety functionality, such as override mode, enables your system to ignore all non-essential faults during emergencies to maintain air quality in the fire exit paths.

Reduced costs

The ACH580 reduces costs, for example, by eliminating dependencies on external controllers. The drive can use its internal PID loops to reach a pressure setpoint by checking the active pressure and adjusting the fan speed accordingly.

Optimal system efficiency

Leverage advanced system monitoring, which controls fans and pumps based on feedback from the drive. Use this information to plan maintenance based on the actual needs of the application. For example, with built-in monitoring, the drive notifies you when it’s time to take action when a fan stalls, a belt breaks, a filter clogs, and more.

Overcome challenges of harmonics!

The low harmonic variant drive has excellent harmonic performance ensuring that the current harmonics in undistorted networks are always less than 3% THDi value. As there is no need to install external harmonic filters or multi-pulse transformers there is are significant cost savings.

Want to learn more? Download below…

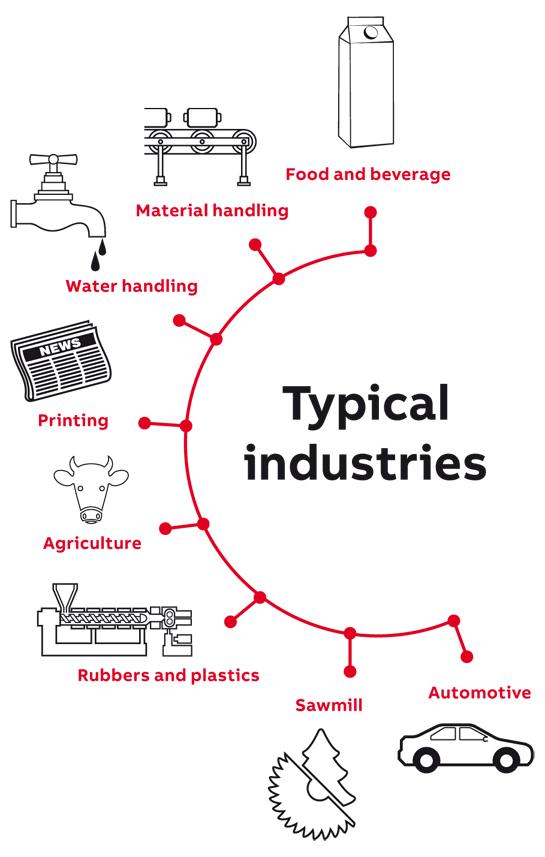

General (ACS580)

Effortless process automation for a broad range of applications

ACS580 is plug-in ready to control your compressors, conveyors, mixers, pumps, fans and many other variable and constant torque applications

Highlights

• All essential features built into the drive

• Straightforward settings menu and assistants for fast commissioning

• Energy efficiency features for optimal energy management and support for energy efficient motors

• Wall-mounted, drive modules and cabinet-built drives to control a variety applications

• Connectivity to most common automation networks and extensive selection of I/O options to match your needs

• ATEX certified thermistor relay for potentially explosive environment (dust areas in F&B)

Features

• Assistant control panel as standard with primary settings and diagnostics menu with various assistants for effortless use of the drive

• Power range 0.75 to 500 kW (3-phase 380 to 415 V, 440 to 480 V)

• Wall-mounted drives, IP21 as standard (UL type 1), IP55 as option (UL type 12 in frame sizes R1-R9)

• Cabinet-built drives, IP21 as standard, IP42 and IP54 as options

• Integrated EMC C2 filter for domestic environments as standard in wall-mounted drives and cabinet-built drives for frames R6 to R9

• Integrated EMC C3 filter for cabinet-built drives as standard

• Built-in patented 2nd generation swinging choke for frames R10 and R11

• Brake chopper up to 22 kW (R3)

• Support for induction, permanent magnet and synchronous reluctance motors (SynRM)

• Safe torque off for implementing safe machinery

• Scalar and vector control for process control

• SIL 3, PL e

• Options:

– Wide range of fieldbus adapters and remote monitoring

– Relay extension, PTC-thermistor, 115/230 V DI plug-in options, ATEX-certified PTC-thermistor, bipolar analog input

– Free entry level PC tool with USB connection on control panel

– Optional Bluetooth enabled control panel

Want to learn more? Download below…

P: +61 3 8360 8533 | W: celltec.com.au | E: sales@celltec.com.au

Truganina (HQ) | 6 Paraweena Drive, Truganina VIC 3029