ACTIVE PROTECTION: Safe Traffic Management in Logistics & Warehousing

How to achieve a safe traffic management system without compromising operational flow.

Improving safety should never mean you have to compromise the efficiency of your operations

Safety implementation can be seen by both workers and employees as an impediment to day-to-day work processes. Creating barriers to how workers can effectively carry out their jobs, which slows down and reduces output levels for an employer. Much of the reason for this is the disjointed and afterthought manner in which safety mechanisms tend to be incorporated to new and existing infrastructure.

The key to ensuring implementation is done in a way that benefits both workers and their employees is one that allow connectivity between elements that were once treated separately.

Implementing the right safety elements within these 3 key areas for a free-flowing safety framework

Dock Safety

Adapting dock operation to allow safe and appropriate access for workers and drivers.

Booms & Locking Gates

Pedestrians crossing loading docks when forklifts are in operation is a constant and dangerous OHS issue. Using booms and locking pedestrian gates, CellTec’s Pedestrian Dock Safety System adapts operation to allow appropriate and safe access. When forklifts are in use during the loading and unloading process, pedestrians are kept safely behind locked gates.

Once this process is complete boom gates are lowered preventing access to forklifts whilst gates are unlocked allowing pedestrian to safely cross the docking area.

Dock Telescopic Gates

Dock gates can serve as a physical safety barrier that can be used in conjunction with PLC and switch controlled security of loading dock bays:

- Telescopic gates extend over the length of tailgates to reach back end of a truck when docked, providing a physical safe barrier on either side of a bay during loading/ unloading.

- Smooth guides allowing gate extension to retract back far enough to allow gates to close together when not in use within the width of the dock doorway.

- Bow latch to hold gates together when in closed position or a keyed and switch locking connected to safety controls can also be integrated.

PLC Controlled Driver Key Lock Boxes: solving issues with staff safety at loading dock bays

- Driver docks at loading dock bay.

- Driver or staff member places truck keys in lock box.

- Keys are confirmed to be in lock box, then access is granted via control button/switch to dock for loading / unloading

- Key lock box is locked while loading / unloading occurs. This ensures that truck does not leave loading bay until loading / unload has been completed and all staff are clear from truck.

- Truck is loaded / unloaded.

- Area is confirmed to be clear and access to remove key is granted via control button / switch.

- Key box unlocks allowing driver to access truck key.

- Driver can now start truck and leave loading dock bay.

Walkway Safety

Automated controlled access, creating safe interaction between vehicles and pedestrians.

Pedestrian Locking Gates

CellTec’s gate locking system prevents access by locking pedestrian gates when a forklift, AGV or another vehicle is detected within a specified area.

Gate locking systems provide pedestrians with the ability to cross safely in areas where vehicles are operating and various activation options and methods allows the locking system to be adapted to suit your environment.

Forklift working with active RF transmitter sending signal to receiving gate locking systems and warning signs within programmed zoned area.

Forklift crossing between 2 zones, both gates in each zone closed to pedestrian traffic while forklift is active within range that has been programmed.

Forklift has exited passed 1st zones programmed range allowing gate to open to pedestrian access. However 2nd gate remains closed as forklift is still within 2nd zones programmed hazardous / operational area.

Hand Railing

Walkway Barriers

Hand railing is a simple and effective barrier that provides clear and safe sectioning between a hazardous area and safe pedestrian walkway. Locking gates can be implemented at as:

- Monitored locking gates, which operate on a safe access protocol.

- Un-monitored but mechanically locking gates, slow access and provide stopping point.

- Simple swing gates, without locking or monitoring. Safe operation via induction procedure.

Protect personnel and pedestrians in walkways from high pallet stacks of stock which may become unstable in adjacent stock warehousing areas.

- Guard barriers manufactured to height to adequately provide protection in relation to potential height of pallet stacks.

- Yellow powder coated for durability of wear and strong visual presence.

- Wall bracing improves strength for circumstance where products may come loose from pallets or pallet stacks themselves become unstable.

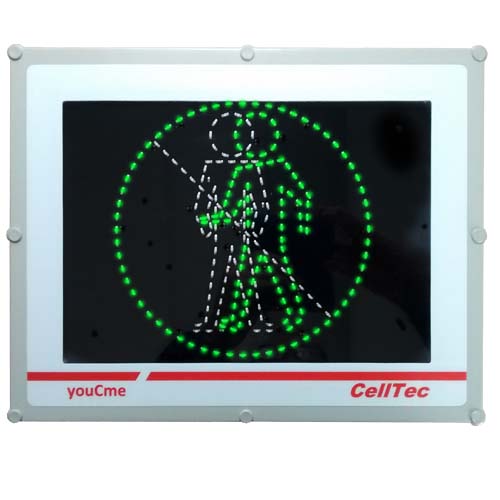

Forklift & AVG Warning

Radio frequency technology for active safety information in working zones.

Forklift / Industrial LED informational and warning signs are designed to highlight traffic conditions when plant hazards such as forklifts and AVG’s are operating within a zone that is also occupied by workers and pedestrians.

These are not just signs, but can be combined with Dock and Walkway Gate Safety systems in a network and interconnected operation.

Benifits of CellTec’s LED activated signs as apposed to traditional signage:

- Transmitters can be easily mounted to any forklift or vehicle.

- You can have multiple transmitters connecting to a single or multiple signs.

- You can easily add additional signs and transmitters to the same zone as you expand and requirements increase.

- Link to operation of Dock and Walkway Boom and Gate setups.

- Adjustable functions via app settings.

- High intensity LEDs increase visual indication.

- Wide viewing angels, ensure warning can be seen from most places.

- Microprocessor control allows for a variety of flashing sequences.

- Both use of LEDs and microprocessor reduce the amount of energy required to power and operate units.

P: +61 3 8360 8533 | W: celltec.com.au | E: sales@celltec.com.au

Truganina (HQ) | 6 Paraweena Drive, Truganina VIC 3029