Leveraging Kuka Robots and CellTec’s Expertise for Advanced Automation Solutions

In the dynamic landscape of manufacturing, the integration of cutting-edge technologies has become essential for businesses striving to stay competitive and efficient. Among these technologies, Kuka robots stand out for their versatility, precision, and reliability. When combined with the expertise of companies like CellTec, specialising in Kuka robot automation projects, the potential for optimising manufacturing processes reaches new heights.

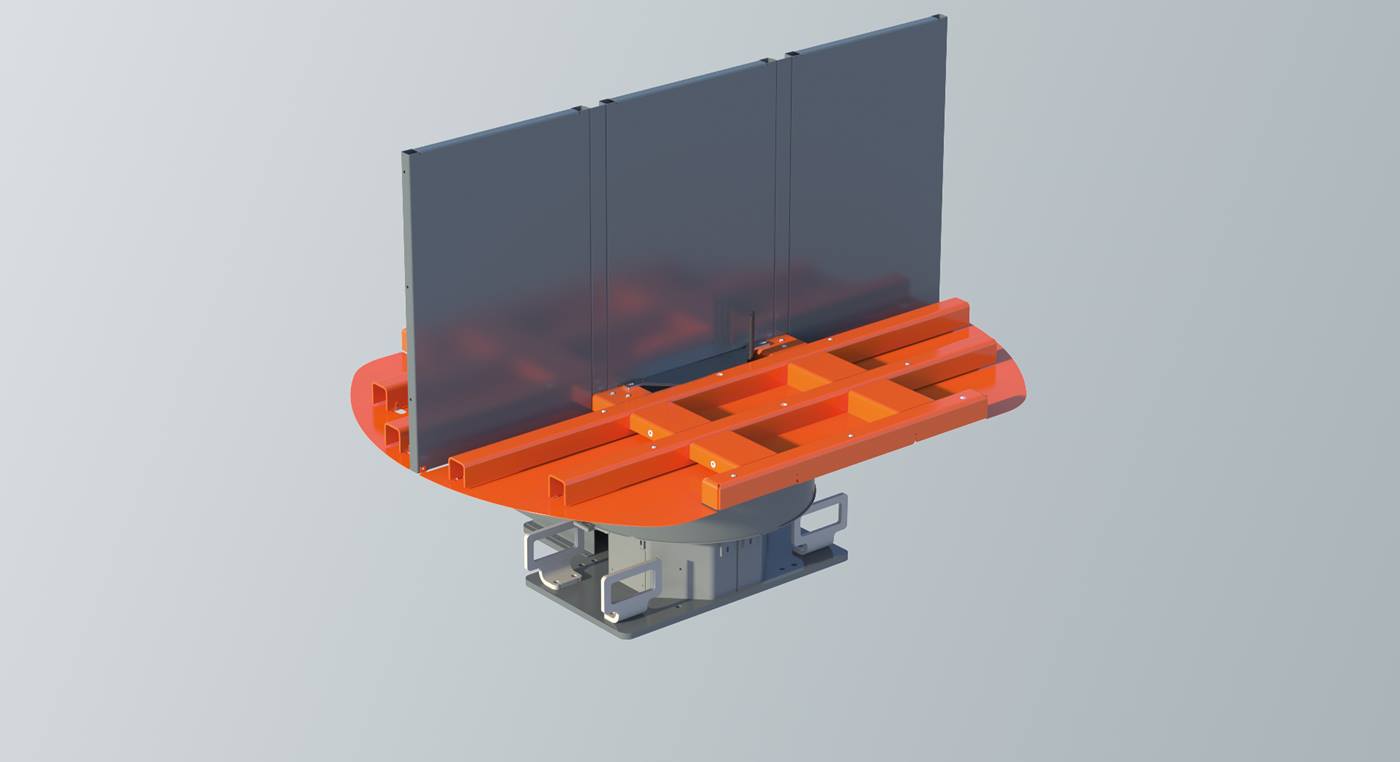

Optimising Workflow with Kuka Robots and Rollovers/Turntables

Rollovers and turntables play a pivotal role in optimizing workflow efficiency, particularly when integrated with Kuka robots. These automation solutions facilitate seamless reorientation and repositioning of assemblies, allowing Kuka robots to access different sides or angles with ease. With CellTec’s expertise in Kuka robot integration, manufacturers can harness the full potential of these advanced systems to streamline their operations.

Enhanced Flexibility and Adaptability

The combination of Kuka robots with rollovers and turntables offers unparalleled flexibility in manufacturing operations. CellTec’s proficiency in designing and implementing Kuka robot automation projects enables businesses to handle diverse product ranges and production requirements without costly retooling or downtime. Rapid changeovers between tasks or product lines become achievable, empowering manufacturers to respond swiftly to market demands.

Ergonomic Solutions for Worker Safety

Incorporating Kuka robots and automated rollovers/turntables not only enhances productivity but also prioritises worker safety and ergonomics. By offloading repetitive or strenuous tasks to robots, CellTec’s solutions reduce the risk of workplace injuries and fatigue. Moreover, the seamless interaction between Kuka robots and rollovers/turntables optimises assembly parts positioning, further minimising strain on human operators.

Streamlined Production Processes

Efficient material handling is crucial for maintaining smooth production flows, and Kuka robots excel in this aspect. CellTec’s integration of Kuka robots with rollovers and turntables ensures seamless loading and unloading of workpieces, minimising bottlenecks and cycle times. This streamlined approach to production not only enhances efficiency but also improves overall throughput and resource utilisation.

Quality Assurance and Consistency

Consistency and precision are hallmarks of Kuka robot automation, bolstered by CellTec’s expertise in implementing robust quality control measures. By presenting workpieces in a controlled manner, rollovers and turntables enable Kuka robots to execute tasks with unmatched accuracy. This meticulous attention to detail translates into superior product quality and reduced variability in manufacturing outcomes.

Future-Proofing Manufacturing Operations

As manufacturing requirements evolve, scalability and adaptability become paramount. With CellTec’s proficiency in Kuka robot automation projects, businesses can future-proof their operations by seamlessly integrating advanced technologies into their workflows. Whether scaling up production volumes or diversifying product lines, the synergy between Kuka robots and rollovers/turntables ensures a cost-effective and sustainable approach to growth.

KUKA Positioners

Find the optimum solution for every positioning task.

KUKA’s catalogue of positions offer a solution for a comprehensive array of production tasks with a portfolio of positioners for payloads from 250 to 12,000 kilograms. Depending on the tasks or assembly requirement at hand, Kuka’s offering can get you the right solution for your application – from welding, metal working, part crimping and assembly.

High productivity

Achieving successful production is made possible by dynamic drives, seamless coordination between robots and positioners, and customisable machine data tailored for optimizing cycle times, resulting in enhanced throughput, reduced reject rates, and swift tool carrier changes.

Efficiency and profitability

The efficiency of robot positioner systems is enhanced by leveraging reliable KUKA robot components, which boast a considerable amount of standardised parts. These preconfigured elements significantly reduce integration time, while the comprehensive simulation capabilities of KUKA further facilitate seamless testing and deployment.

Uncompromising quality

KUKA robots and positioners demonstrate exceptional precision and virtually error-free operation across all CP applications. Their flexible and repeatable performance ensures consistently flawless workpieces.

Integration – simple, safe, fast

With electrically insulated face plates, straightforward mastering using the KUKA EMD, and simplified programming, Kuka solutions offer proven and familiar methods for efficient integration and rapid implementation of customised customer solutions, all supported by standardised interfaces.

Customised solutions from a single source

The modular system, encompassing robots, positioners, linear units, and various components, guarantees straightforward integration of customer-specific solutions, facilitating precise coordination between positioners and workstations.

KUKA’s ready2_pilot

The intuitive controller package teaching simple and manual guidance of robots

KUKA’s ready2_pilot is a world’s first controller package quickly mounted on the robot and can be used directly without complex programming. With manual guidance, users can effortlessly teach robots the desired sequences, spanning from precise welding to rough palletisation, and accommodating both small and heavy-duty robots. ready2_pilot offers a straightforward solution for customising robots to meet specific requirements.

Intuitive, reorienting 6D mouse

Using the intuitive 6D mouse, operating KUKA ready2_pilot is effortless and requires no training. The mouse, easily secured with adapter plates, can be conveniently utilised from various positions, always within the user’s reach.

Connectivity and flexibility

KUKA ready2_pilot’s wireless design is compatible with all standard KUKA robots, providing operators with maximum freedom and flexibility in control.

Freedom of motion to the right degree

Achieve precise robot movement by deactivating unnecessary directions, allowing exclusive control over desired paths. This prevents unintended slipping during motion and minimises the need for time-consuming corrections.

Adaptable navigation keys

Two buttons located on the side of the 6D mouse provide rapid access to customisable functions. Whether it’s opening and closing a gripper, adjusting process parameters, or saving motions in the robot program, a simple click is all it takes, saving valuable time.

KUKA’s smartPAD Teach Pendant

Ergonomic robot control panel with capacitive touch display

KUKA smartPAD teach pendant was designed to master even complex operating tasks easily. It can be deployed universally and is easy to operate, even for inexperienced users.

Universal application

Operating all KUKA robots running on KSS and Sunrise.OS in the preferred language is made possible with the KUKA smartPAD. This device is hot-pluggable, allowing for seamless connection and disconnection at any time.

Comfortable handling

Utilisation of straps and handgrips adaptable for both hands significantly streamlines operator control. Additionally, an optional shoulder strap alleviates operator fatigue, especially beneficial during prolonged and demanding projects.

Simple robot jogging with ergonomic 6D mouse

The 6D mouse provides intuitive control for jogging and reorienting the robot in either three or six degrees of freedom.

Eight jog keys

The KUKA smartPAD allows direct control of up to eight axes or external axes using separate jog keys, eliminating the need for switching between controls.

Integrated protectors

In case of a fall, integrated protectors provide optimal protection. The scratch-resistant display and IP 54 protection rating allow for operation in demanding industrial environments.

Simple data transmission

Accessible via two convenient ports, direct saving and loading of application programs, as well as connection of other supported USB devices, are facilitated with ease.

Efficient operation

Input is swift and effortless through a vibrant, capacitive touch display featuring an 8.4″ screen with high luminosity.

Maintenance-friendly design

The presence of a service flap facilitates easy cable replacement as needed.

P: +61 3 8360 8533 | W: celltec.com.au | E: sales@celltec.com.au

Truganina (HQ) | 6 Paraweena Drive, Truganina VIC 3029