Maximising Efficiency and Safety: Integrating AMRs with CellTec’s ZONE Safety Systems Fencing in Warehousing and Logistics

In the continuously evolving landscape of warehousing and logistics, companies are seeking innovative solutions to optimise operational efficiency while prioritising safety. Among the transformative technologies driving this evolution, Autonomous Mobile Robots (AMRs) have emerged as game-changers, offering unprecedented flexibility, scalability, and productivity gains. However, integrating AMRs seamlessly into warehouse environments necessitates robust safety measures, making industrial safety fencing a critical component. In this context, CellTec’s ZONE Safety Systems fencing stands out as the premier choice for safeguarding both personnel and assets.

Efficiency Through Automation

The advent of AMRs has ushered in a new era of automation, revolutionising various warehouse tasks and significantly reducing reliance on manual labour. These autonomous robots navigate complex warehouse layouts with ease, performing tasks such as goods transportation, picking, packing, and inventory management efficiently and accurately. By leveraging AMRs, warehouses achieve higher throughput rates, faster order fulfillment, and improved overall operational efficiency.

Flexibility and Adaptability

AMRs offer unparalleled flexibility and scalability, unlike traditional fixed automation systems. Their ability to adapt to dynamic warehouse environments and changing operational needs makes them indispensable assets for modern logistics operations. With AMRs, warehouses optimise space utilisation, minimize congestion, and easily accommodate fluctuations in demand without costly infrastructure modifications.

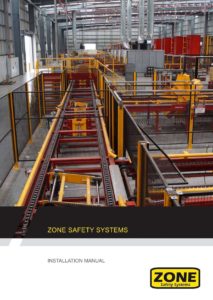

Enhancing Safety with CellTec’s ZONE Safety Systems Fencing

While AMRs enhance efficiency, ensuring the safety of workers and assets remains paramount. Industrial safety fencing provides a robust solution to mitigate risks associated with AMR operations, and CellTec’s ZONE Safety Systems fencing stands at the forefront of safety solutions. By creating designated pathways and segregating zones within the warehouse, ZONE Safety Systems fencing prevents collisions between AMRs, other equipment, and personnel. It serves as a physical barrier to restrict access to hazardous areas, ensuring compliance with regulatory standards and safeguarding both workers and assets.

Optimising Workflow

The integration of AMRs with CellTec’s ZONE Safety Systems fencing enables warehouses to optimise workflow and resource allocation effectively. By defining clear pathways for AMRs and segregating human work areas, warehouses minimise interference between robotic and manual operations, reducing bottlenecks and streamlining processes. This optimised workflow enhances productivity, accelerates order fulfillment, and improves overall operational performance.

Achieving Cost Savings

While the initial investment in AMRs and CellTec’s ZONE Safety Systems fencing may seem substantial, the long-term benefits outweigh the costs. By maximising efficiency, minimising downtime, and reducing the risk of accidents and errors, warehouses achieve significant cost savings over time. The labor optimisation enabled by AMRs frees up human resources for more value-added tasks, while the enhanced safety provided by ZONE Safety Systems fencing mitigates potential liabilities and associated costs.

Looking Ahead

The Future of Warehousing and Logistics

As technology continues to advance, the integration of AMRs with CellTec’s ZONE Safety Systems fencing will play an increasingly pivotal role in shaping the future of warehousing and logistics. With ongoing innovations in robotics, artificial intelligence, and automation, warehouses will evolve into highly efficient, safe, and agile operations centres. By embracing these transformative technologies and prioritising safety with CellTec’s ZONE Safety Systems fencing, businesses can stay ahead of the curve and thrive in an increasingly competitive marketplace.

The integration of AMRs with CellTec’s ZONE Safety Systems fencing represents a paradigm shift in warehousing and logistics operations. By combining the efficiency of autonomous robotics with the unparalleled safety provided by ZONE Safety Systems fencing, warehouses achieve optimal operational flow, enhance productivity, and ensure the well-being of their workforce. As the industry embraces these advancements, the future of warehousing and logistics shines brighter than ever before.

AMR Safety Fencing

Future of safety in warehousing is here

ZONE Industrial safety fencing plays a crucial role in warehouses, especially those utilising Autonomous Mobile Robots (AMRs), by providing numerous benefits to ensure the safety of workers, protect assets, comply with regulations, and optimise operational efficiency. It serves as a critical component of a comprehensive safety strategy in modern warehouse environments.

Worker Safety

The primary purpose of safety fencing is to protect workers from potential hazards. In a warehouse with AMRs, which are autonomous and may move unpredictably, safety fencing ensures that workers are separated from moving machinery, reducing the risk of accidents and injuries.

Collision Prevention

AMRs can operate at relatively high speeds and may traverse throughout the warehouse floor. Safety fencing helps to create designated pathways for AMRs, preventing collisions with other equipment, stationary objects, or personnel.

Zone Segregation

Fencing can be used to create distinct zones within the warehouse, separating areas where AMRs operate from areas where human workers perform tasks. This segregation helps to minimise interference between human and robotic activities, improving efficiency and safety.

Restricted Access

Safety fencing can limit access to certain areas of the warehouse, such as loading docks, machinery, or hazardous zones, ensuring that only authorised personnel are allowed entry. This reduces the risk of accidents and unauthorised interactions with equipment.

Compliance

Many regulatory standards and safety guidelines mandate the use of safety fencing in industrial environments to protect workers and comply with occupational health and safety regulations. Implementing safety fencing demonstrates a commitment to safety and helps to ensure compliance with relevant standards.

Asset Protection

Safety fencing provides a physical barrier that helps to protect both AMRs and other valuable assets within the warehouse from damage caused by collisions or unauthorised access.

Enhanced Workflow

By clearly defining pathways and zones within the warehouse, safety fencing can optimise the flow of goods and materials, as well as the movement of AMRs, leading to increased efficiency and productivity.

Risk Mitigation

Utilising safety fencing alongside AMRs reduces the risk of accidents, equipment damage, and operational disruptions, ultimately minimising potential liabilities and associated costs.

Scalability and Adaptability

Safety fencing systems are often modular and customisable, allowing for easy adaptation to changing warehouse layouts or operational requirements. This scalability ensures that safety measures remain effective as the warehouse evolves.

Increased Confidence and Morale

Providing a safe working environment through the implementation of safety fencing instils confidence among workers and fosters a positive safety culture within the organisation, leading to higher morale and productivity.

ZONE Safety Systems

Modular solutions for effortless safety, simplified installation

ZONE Safety Systems Industrial Safety Fencing is meticulously engineered by CellTec and proudly crafted in Australia at our state-of-the-art Truganina VIC facility. With over 25 years of local manufacturing experience, we are committed to providing tailored solutions that prioritise both safety and productivity in your workplace.

Local Design Assistance

Our local design support team is here to assist you with your project layout. From initial planning to installation adjustments, we offer personalised guidance and expertise to ensure maximum safety and efficiency. Leveraging our knowledge of local regulations, we tailor solutions to meet your needs, providing valuable insights for project success.

Simplified Specification

Our standardised dimensions enable effortless component selection. With consistent panel use for fixed fences and doors, achieving identical clearances facilitates seamless configuration adjustments during installation. Wall lengths are easily calculated by adding panel widths plus 100mm per post. Accessories seamlessly integrate with standard panels for hassle-free access door conversion.

Effortless Installation

Our posts and brackets seamlessly align, facilitating easy assembly. This design enables the straightforward fitting of various components, from interlock switches to sliding door tracks. Panels rotate freely on the brackets, offering versatility for angled configurations and flexibility during installation.

Responsive Local Engineering and Manufacture

With our local engineering and manufacturing support, we prioritise swift action and adaptability to meet your project needs. Whether it’s making quick modifications or accommodating customisation requirements during installation, our team is ready to respond promptly. Leveraging our proximity, we ensure efficient communication and seamless coordination to address any challenges that arise. Our agile manufacturing capabilities allow us to rapidly produce tailored solutions, ensuring that your project stays on track without compromising quality or safety.

Adaptable and Reusable

In response to evolving production needs, adjustments and reconfigurations of safety guarding are frequently necessary. Our ZONE Safety Fencing streamlines this process, allowing for swift interchange and reconfiguration of panels, access points, or attached components. Our modular guarding design fosters reusability and redeployment by facilitating effortless alterations. Additionally, we offer a comprehensive range of accessories, encompassing electrical and trapped key interlocks, light curtains and grids, safety relays and controllers, safety mats, warning beacons, and sirens, to cater to your specific needs.

GET IN TOUCH

How Can We Help?

Contact us to request a quote or to schedule a consultation with our team.

P: +61 3 8360 8533 | W: celltec.com.au | E: sales@celltec.com.au

Truganina (HQ) | 6 Paraweena Drive, Truganina VIC 3029