NEXT GEN: Anti-Microbial Conduit for Food & Beverage

The ideal conduit system for the Food & Beverage industry

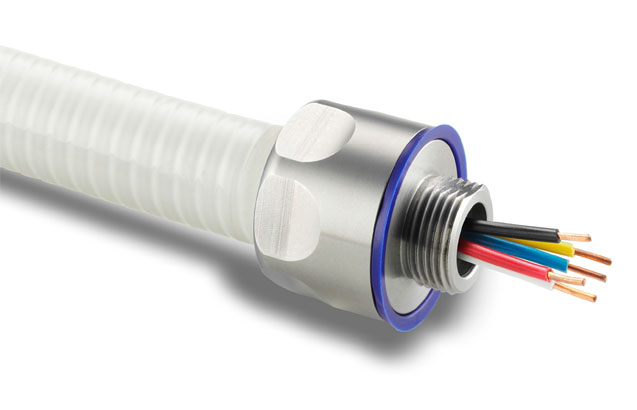

The innovative ABB Adaptaflex food and beverage conduit, was designed to protect complex processing equipment with sensitive electrical wiring systems, controls and automation.

Conduits and fittings can become a home for bacteria and pose a direct threat to food manufacturing. It is well known and proven that bacteria can adapt and survive on the various surfaces, meaning a structured and thorough cleaning regime is a must for clean equipment and food safety.

The Adaptaflex conduit provides a solution that enable food and beverage processors to increase revenue, plant sustainability, food safety, brand and production quality.

- DuPont Hytrel® thermoplastic jacket – FDA, EC and FSA compliant with integral anti-microbial protection incorporating an ionic silver additive

- Single piece liquid tight 316 Stainless Steel fittings – An industry first.

Partnering with BioCote - global antimicrobial solution provider

ABB has formed a commercial partnership with anti-microbial protection experts, BioCote, producing a cable protection solution that can withstand the challenging environment of the food and beverage industry, and is proven to eradicate up to 99.9% of contaminating bacteria. The new liquid tight conduit from ABB for Adaptaflex, features a smooth FDA, EC and FSA compliant DuPont Hytrel® thermoplastic jacket, with integral anti-microbial protection incorporating an ionic silver additive and an industry first, single piece liquid tight 316 Stainless Steel fitting to complete the system.

‘… proven to eradicate up to 99.9% of contaminating bacteria…’

Based on a silver glass powder matrix, the anti-microbial additive provides a slow release of silver ions to the surface of the product protecting against bacterial contamination and the growth of mold, whilst providing highly chemical resistant properties.

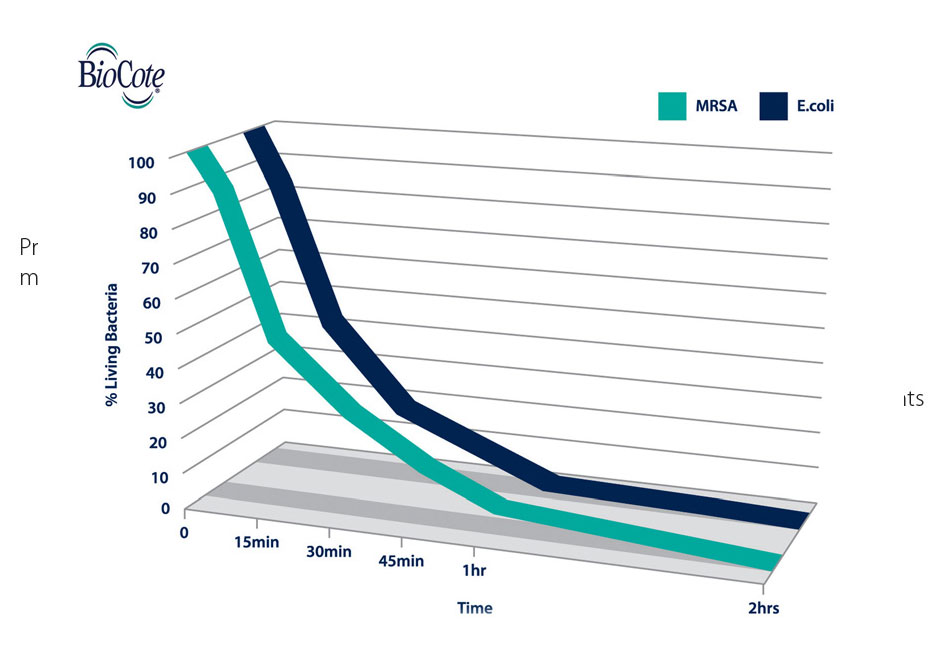

The liquid tight nature of the system – up to IP69 – and anti-microbial protection, combine to protect power and data cables within, from extreme temperatures and the subsequent wear from regular daily wash downs. Crucially, the integral anti-microbial protection, which neither wears off or washes away, attacks both gram negative and gram positive bacteria, such as MRSA and E.coli, with testing showing reductions in bacteria within 15 minutes compared to an untreated surface.

“…bacterial reductions of up to 80% in just 15 mins…”

Guy Charteris, Partner Development Manager at BioCote Ltd comments:

“As we have seen in recent years, it can take just a single bacterial infection to eradicate decades of consumer trust, crippling a company’s finances in the process. Though anti-microbial technology should not be viewed as a replacement to cleaning, the addition of anti-microbial additives, enhances the system integrity proven by our repeated testing and observations showing bacterial reductions of up to 80% in just 15 mins on the treated conduit systems compared to untreated systems, rising to a 99% bacteria reduction in two hours.”

Internal Wiring Networks

The liquid tight nature of the system – up to IP69 – steel core, anti-microbial protection and new single piece Stainless Steel fitting, combine to protect power and data cables from within, allowing machinery to operate efficiently, safely, and hygienically, without compromising production and systems.

Corrosion Resistant Material

Food and beverage facility cleaning and sanitation crews often use high-pressure wash down cleaning equipment with high-temperature chemical solutions, with these processes in mind, ABB developed their food and beverage Adaptaflex conduit system using chemically resistant materials in their construction.

Reducing Product Wastage and Downtime

Food and beverage processing plants require a high sustainability level from their electrical systems, because shutdowns can cost from minutes’ to days’ worth of production if a batch must be scrapped.

P: +61 3 8360 8533 | W: celltec.com.au | E: sales@celltec.com.au

Truganina (HQ) | 6 Paraweena Drive, Truganina VIC 3029